Headlines

Diamond blade uses and applications.

24 October 2022

What is a diamond blade?

What is a diamond blade?Diamond blades are extremely tough blades which feature segments, containing synthetic diamond, on the cutting edge allowing them to grind through ultra-hard and abrasive materials, such as stone, brick and concrete.

They provide very clean and fast cuts when used on extremely hard concrete and masonry materials and are used in a wide range of applications. For example, landscapers will use them to cut paving slabs for an outdoor patio, and a bricklayer will use them to cut bricks.

Diamond blades don’t cut through the material, instead it grinds it due to its rectangular tooth shape. If you were to use a standard TCT saw blade or a blade with teeth on masonry/concrete materials, the blade would wear extremely fast. The rectangular tooth shape also helps to give the material a smooth cut finish.

Diamond blades vary in size, quality, segment bond and diamond concentration. You can also get thin kerf diamond blades which provide an extremely clean finish and increase cutting efficiency due to the width of the blade resulting in less material getting removed.

When choosing diamond blades, it is important to get the correct blade that will suit your application to ensure it provides a clean, fast cut, and is specific for the material, and type of cut needed.

What can a diamond blade cut?

Diamond blades are used for cutting hard materials including:

- Porcelain tile

- Granite

- Marble

- Slate

- Natural stone

- Concrete

- Brick

- Ceramic tile

- Sandstone

- Clay

- Engineering bricks

- Roof tile

- Asphalt

- Cement

- Lignacite blocks

How do I know which diamond blade to use?

Diamond blades vary in size, quality, segment bond and diamond concentration.The diamond concentration of the segment is the most important factor in determining what the blade will cut.

Diamond blades vary in size, quality, segment bond and diamond concentration.The diamond concentration of the segment is the most important factor in determining what the blade will cut.The higher the diamond concentration, the better it is at cutting softer and more abrasive materials, but the cutting speed will need to be slower. It is better to use lower diamond concentration blades when cutting brittle and extremely hard materials.

Most manufactures however do not refer to the level of diamond concentration in the segment but rather simply state what their blade is suitable for and the maximum speed the blade should run at. This is for user ease and to simplify the technicalities around diamond blades.

At DART, we only recommend using your diamond blade on the recommended materials, this is to ensure you get the maximum life out of your blade, and have a quality cut every time.

Can diamond blade cut wood?

Diamond blades are not recommended for cutting wood. This is due to the harsh grit of the blade, which will result in the wood fibers getting ripped apart when being cut, resulting in the cut finish being very rough. It could also easily create crooked cuts.

Diamond blades are meant to be used to cut very hard materials such as concrete, so it can easily damage soft materials such as wood. If you are looking to cut through wood, then we recommend using our gold TCT wood saw blades, which feature ATB tooth configuration for a professional finish and long cutting life.

Cut you cut tile with a diamond blade?

Yes, diamond blades are used for cutting hard materials, including tile. But when you are cutting tile, you need to ensure that the cut is done at a slower rpm, and for best results, a water feed is recommended. This will guarantee you get a smooth clean cut, without chipping the tile.

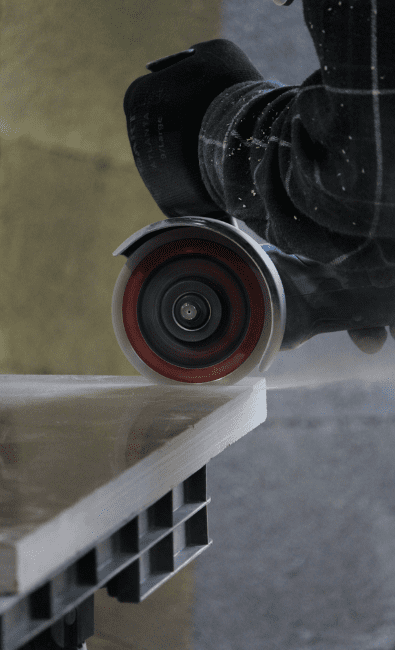

If you cut the tile too fast, this will result in heat buildup, which will result in the segments becoming blunt a lot faster, reducing the life of your diamond blade.

There are different types of tile, including ceramic tile and grade (PEI) 5 tile. You will need to use different blades depending on the tile you are cutting to ensure a quality result. Ceramic tile is the easiest to cut, whereas grade (PEI) 5 porcelain is the hardest to cut, and will need a professional high-quality blade that is suitable for cutting the toughest of porcelains. More caution is needed when cutting very tough porcelain, such as grade 5, as it can chip a lot easier.

Can you cut glass with a diamond blade?

Can you cut glass with a diamond blade?Diamond blades will not cut glass to a good standard. Some manufactures state that their blades are able to cut glass, but a diamond blade suited for masonry cutting will not cut glass efficiently. They can easily chip the edges of the glass and leave a rough cut.

Furthermore, If the glass gets overheated it can easily shatter or crack, so at DART, we don’t specify cutting glass on any of our diamond blades.

Can you use a diamond blade to cut metal?

Some diamond blades can cut metal, but it all depends on the blade’s application, and whether the manufacture states that it can be used on metal. If you use a blade that isn’t meant for cutting metal, then this will damage the blade and reduce its longevity.

Some of DART’s diamond saw blade range are able to cut thin metal such as the diamond landscaper multipurpose blade, with sizes ranging from 115mm to 350mm.

How to sharpen a diamond saw blade?

To prolong the life of your diamond saw blade, it is important to sharpen your blade in order to maintain a consistent high-quality cut. This can be done by simple running your blade through a soft and abrasive material such as a breeze block to sharpen the blade.

You can also sharpen your diamond saw blade by using a sharpening stone, which you run the blade against in order to expose the diamonds again.

You will know if you need to sharpen your blade when the cutting surfaces glaze over which can produce hot spots along the cutting edge.

By using either of the above methods to sharpen your blade, you will be re-exposing the synthetic diamond in the segment, giving your blade a longer life, and improving the speed and quality of your cut.

How long will a diamond blade last?

The life of your diamond blade depends on various factors such as the quality of the blade and what materials it cuts. Some very good quality blades can last over 120 cutting hours in correct conditions, whereas low quality diamond blades can sometimes only last up to 12 hours, or even half that if you are dry cutting.

The life of your diamond blade depends on various factors such as the quality of the blade and what materials it cuts. Some very good quality blades can last over 120 cutting hours in correct conditions, whereas low quality diamond blades can sometimes only last up to 12 hours, or even half that if you are dry cutting. It is known that diamond blades can be used up to 100 times longer than other abrasive blades, due to the very hard diamond on the blade’s teeth.

Very few manufactures will state a specific amount of time that each blade will last for, as it depends on the material, the cutting technique, the speed of the cut and overall cutting conditions.

Using a water feed whilst cutting helps to increase blade longevity.

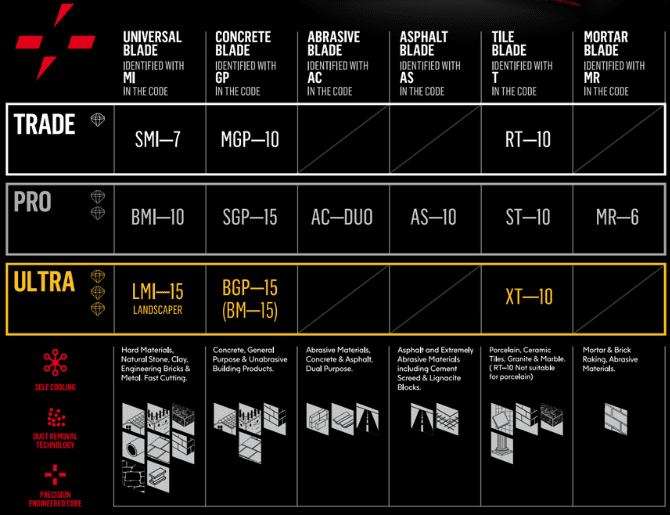

DART’s diamond blade range

At DART, we have a very extensive range of diamond blades. Our range is highly respected and manufactured to the highest of standards, with ISO accreditation and are EN certified. They are specifically designed for the construction industry and professionals; they are blades you can count on.

DART’s diamond blade range include three different qualities across a wide range of applications, to ensure you are choosing the correct blade for your job.

Check out DART’s professional diamond blade range here for more information - Diamond Blades - Diamond Blades for Circular Saws | DART Tool Group

We love to see our DART products in action! Be sure to tag DART Tool Group on Facebook, Instagram and LinkedIn to share your experiences of the DART diamond blades!

Kester Paterson | DART Tool Group