Headlines

Ultimate Guide to Circular Saw Blades

07 June 2023

In this guide, we will cover everything you need to know about circular saw blades, to help you choose the correct blade for your saw, material and application.

Contents:

- What are circular saw blades?

- How do I choose a circular saw blade?

- How to change the blade on a circular saw?

- How to sharpen a TCT circular saw blade?

- How long does a circular saw blade last?

- How thick is a circular saw blade?

- How many teeth for a TCT circular saw blade?

- What direction does a circular saw blade rotate?

- Can you put two blades on a circular saw?

- What is the best saw blade for plywood?

- Can I cut wood with nails?

- Are circular saw blades and table saw blades the same?

- DART's circular saw blade range.

- Saw blade compatibility

What are circular saw blades?

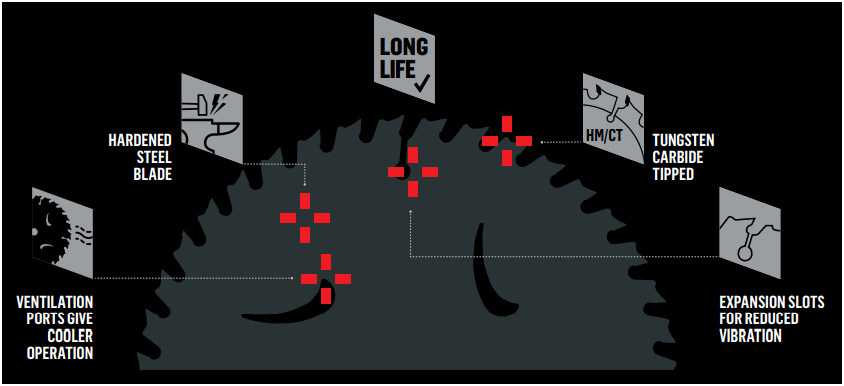

Circular saw blades are for circular saws and enable efficient cutting through a rotary motion. The teeth along the outer edge help provide accurate and consistent cuts when cutting through materials. A wide range of circular saw blades exist, varying in thickness, size, tooth type, number of teeth, and cutting capabilities.

Primarily employed for woodwork applications, circular saw blades proficiently cut through diverse wood types including softwood, hardwood, plywood, and MDF. However, certain blades are also capable of efficiently cutting through metals (including stainless steel), plastics, and man-made materials (such as fibre cement board and composite materials). Consequently, when selecting a circular saw blade,

it becomes imperative to consider the specific requirements of the task at hand, ensuring compatibility with the desired material and achieving optimal results.

it becomes imperative to consider the specific requirements of the task at hand, ensuring compatibility with the desired material and achieving optimal results.Circular saw blades are widely acclaimed power tool accessories extensively utilized by skilled joiners, carpenters, and woodworking enthusiasts for efficient wood cutting. These blades boast exceptional speed, enabling swift completion of tasks, thereby enhancing productivity for professionals.

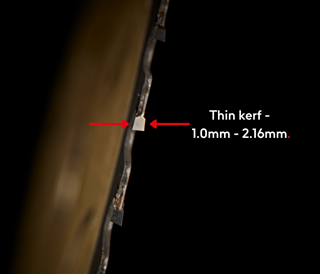

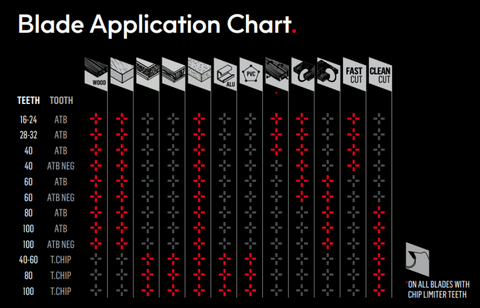

The selection of a blade is influenced by factors such as the number of teeth and tooth configuration, which play a vital role. Blades with a higher tooth count are preferred for achieving smoother cuts. Additionally, different types of teeth are designed to meet specific cutting requirements. Examples include Tungsten Carbide Tipped (TCT) teeth, which can be categorized as Alternate Top Bevel (ATB), Alternate Top Bevel with Negative Rake Angle (ATB NEG), or Triple Chip Ground (TCG). Another specialized tooth type is polycrystalline diamond (PCD) teeth.

In addition, circular saw blades are available in a wide range of sizes, encompassing diameter, bore, kerf, and body dimensions. This assortment allows users to select blades that align precisely with their equipment and project specifications, ensuring optimal performance and accuracy.

How do I choose a circular saw blade?

When selecting a circular saw blade, it is crucial to consider several factors to ensure optimal performance and desired outcomes. Begin by examining your saw to determine the appropriate bore size and dimensions required for a proper fit. Additionally, consider the specific material you intend to cut. For instance, if you are working with plastic, it is essential to choose a blade specifically designed for cutting plastic. Various blade types are available, such as TCT blades, PCD blades and thin kerf blades, each tailored to different materials and cutting applications.

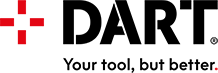

To achieve the desired cut quality, you must also consider the number of teeth on the blade and the associated cut type. DART offers five distinct cut types: coarse finish, medium finish, fine finish, extra fine finish, and fine finish for plastics and laminates. The number of teeth on the blade directly affects the smoothness of the cut, with a higher tooth count resulting in a smoother finish.

Furthermore, it is essential to determine the appropriate cutting speed for your specific blade to prevent blade breakage and ensure clean and accurate cuts. Always refer to the manufacturer's recommendations for the optimal cutting speed. Cutting at excessively high speeds can lead to blade overheating and blunten the teeth, affecting the blade longevity.

DART offers four different tooth types: TCT Alternate Top Bevel (ATB), TCT Alternate Top Bevel with Negative Rake Angle (ATB NEG), TCT Triple Chip Grind (TCG), and Polycrystalline Diamond (PCD). Each tooth type is designed for specific cutting applications, and their individual characteristics can be explored for a better understanding of their suitability for different materials and cutting needs.

How to change the blade on a circular saw?

To change the blade on a circular saw, it is essential to prioritize safety by disconnecting the saw from any power source, such as batteries or power cords, to mitigate the risk of accidental activation. This precautionary measure is crucial, as even experienced professionals can inadvertently trigger the saw's start button.

After ensuring the saw is powered down, follow these steps to replace the blade effectively:

- Locate the arbor nut, positioned in the center of the blade, which secures it to the saw. If your circular saw is equipped with a locking button, engage it to immobilize the blade while loosening the arbor nut.

- Using an appropriate wrench or tool, carefully loosen and remove the arbor nut. Take care to avoid damaging the blade or other components during this process.

- Once the arbor nut is removed, gently slide the existing circular blade out of the saw, making note of its orientation for future reference. At this point, you may choose to either sharpen the blade or replace it entirely, depending on its condition.

- When inserting a new blade or reattaching the sharpened one, ensure it aligns with the saw's arbor. Slide the blade into place, ensuring it fits securely within the arbor assembly.

- Finally, reattach the arbor nut and tighten it firmly using the appropriate wrench or tool. This step is crucial for maintaining a secure and stable connection between the blade and the saw, preventing any potential accidents.

How to sharpen a TCT circular saw blade?

To maximize the lifespan of your circular saw blade and ensure consistent, high-quality cuts, regular sharpening is essential. Signs such as sluggish cutting, burn marks, or increased chipping or tearing of materials indicate that the blade has become dull.

Various methods can be employed to sharpen a circular saw blade effectively. One option is to utilize specialized grinding machines designed specifically for this purpose. These machines offer precise sharpening of each tooth and significantly reduce sharpening time. It is crucial to ensure that the sharpening machine is appropriately tilted to match the angle of the blade's teeth and can accommodate the size of the blade being sharpened.

Using a table saw is a quick method of sharpening circular saw blades, particularly those with tungsten carbide tips. However, it is essential to ensure that the sharpening blade used to sharpen the dull blade is thin enough to fit in the gullets between each tooth. By grinding the blunt teeth against the sharpening blade, each tooth on the dull circular saw blade can be effectively sharpened.

We recommend using a professional saw doctor to sharpen your blades to ensure best practice and safety.

By employing suitable sharpening methods, professional tradesmen can extend the lifespan of their circular saw blades, maintain cutting precision, and achieve optimal results.

How long does a circular saw blade last?

The lifespan of a circular saw blade can vary based on several factors, including the blade's quality, the materials being cut, and the cutting technique employed. On average, a circular saw blade can last anywhere from 12 to 120 hours of use. However, it is important to note that higher-quality blades tend to have a longer lifespan compared to standard blades.

To maximize the longevity of your circular saw blade and avoid frequent replacements, it is recommended to sharpen the blade periodically. This maintenance practice can significantly extend the blade's life and save you the expense of purchasing new blades. A high-quality tungsten carbide blade with high levels of tungsten on it, can typically be sharpened up to four times, ensuring optimal performance over an extended period.

By investing in quality blades and practicing regular maintenance, such as sharpening, you can maximize the lifespan of your circular saw blades, reducing costs and achieving consistent cutting results.

How thick is a circular saw blade?

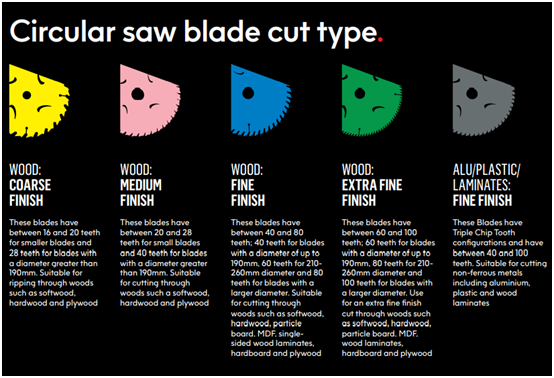

Circular saw blades come in various thicknesses. There are two thicknesses measured on a saw blade: the body, and the kerf. The body measures the thickness of the blade, and the kerf is defined as the width of material that is removed from the cutting/sawing process, and is typically measured by the thickness of the tooth.

The kerf thickness of a blade typically ranges from 1.5mm to 3mm. Thin kerf blades, which are exceptionally thin, offer the advantage of minimizing waste, requiring less power for cutting, and achieving higher efficiency compared to standard blades. Standard kerf saw blades are sometimes the preferred option for very straight and accurate cuts especially when using a powerful corded saw.

The kerf thickness of a blade typically ranges from 1.5mm to 3mm. Thin kerf blades, which are exceptionally thin, offer the advantage of minimizing waste, requiring less power for cutting, and achieving higher efficiency compared to standard blades. Standard kerf saw blades are sometimes the preferred option for very straight and accurate cuts especially when using a powerful corded saw.It is worth noting that the body of the blade is always thinner than the teeth. This design feature serves a crucial purpose by preventing excessive friction and rapid heat buildup during cutting. If the blade maintained a uniform thickness throughout, it would result in burn marks on the material being cut and slow down the cutting process due to increased friction.

By selecting the appropriate thickness and considering the design aspects of a circular saw blade, professionals can optimize their cutting performance while minimizing waste and ensuring efficient operation.

How many teeth for a TCT circular saw blade?

TCT Circular saw blades are available with varying numbers of teeth, providing options to suit different cutting requirements. The number of teeth on a blade directly influences the smoothness of the cut. Blades with fewer teeth are suitable for fast, rough cuts that do not require high precision or a clean finish. On the other hand, blades with a higher tooth count deliver smoother cuts with greater precision.

Circular saw blades typically range from 12 to 100 teeth. At DART, we offer a selection of five different cut types: coarse finish, medium finish, fine finish, extra fine finish, and fine finish specifically designed for plastics and laminates. For those seeking exceptionally clean and precise cuts, blades with a fine or extra fine finish cut type are recommended.

By selecting the appropriate number of teeth and cut type for a circular saw blade, users can achieve their desired cutting results, whether it's a fast rough cut or a precise finish.

This does not apply to TCT Saw Blades for cutting metal, as the number of teeth generally stay the same, and don’t make a difference to cut quality.

What direction does a circular saw blade rotate?

Circular saw blades typically rotate in a clockwise direction, although this may vary depending on the specific saw and its design. To ensure proper installation, most reputable saw brands include an arrow on both the saw body and the blade itself, indicating the correct direction of blade rotation. Aligning the arrows in the same direction guarantees the correct insertion of the blade into the saw.

The direction of cutting, whether clockwise or counterclockwise, is determined by the type of saw being used. In handheld circular saws, for instance, the cutting deck is located on the underside of the metal plate. As a result, the blade rotates in a manner that pulls the material upwards towards the cutting deck. Conversely, in mitre saws, where the cutting deck is positioned on top, the blade rotates in a manner that pulls the material downward.

By following the manufacturer's instructions and ensuring proper alignment of the arrows, users can confidently determine the correct rotation direction for their circular saw blades, resulting in safe and effective cutting operations.

Can you put two blades on a circular saw?

In certain cases, it is possible to utilize two circular saw blades simultaneously, but this requires the use of a specialized tool known as a dual blade circular saw. These dual blade saws are designed to accommodate two blades that rotate in opposite directions, resulting in exceptionally smooth cuts. This unique configuration allows for cutting both forwards and backwards, making it particularly effective for fine materials and metal. One of the key advantages of dual blade saws is their ability to eliminate kickback, providing enhanced control compared to single-blade saws.

It is important to note that attempting to use two blades on a regular saw without the proper mechanism to hold them in place can lead to damage to both the blades and the saw itself. Additionally, using two blades without the appropriate rail guides and following the tapered hole on the circular saw is not recommended. This approach can pose challenges in terms of controlling the tool due to the added weight of two blades, making it difficult to achieve straight and consistent cuts.

To utilize dual blades effectively and safely, it is advisable to invest in a dedicated dual blade circular saw specifically designed for this purpose. These specialized tools offer the necessary features and mechanisms to ensure optimal performance and cutting precision.

What is the best saw blade for plywood?

Plywood is composed of thin layers of wood that are bonded together, with each layer having its grain oriented perpendicularly to the adjacent layers. This construction enhances the strength of the plywood but also renders it susceptible to chipping during cutting.

Plywood is composed of thin layers of wood that are bonded together, with each layer having its grain oriented perpendicularly to the adjacent layers. This construction enhances the strength of the plywood but also renders it susceptible to chipping during cutting.When it comes to cutting plywood, we recommend using a circular saw blade with a minimum of 40 teeth or more. Alternatively, you can opt for a blade with negative angle teeth, such as DART's gold TCT aluminum, plastic/laminate saw blades. These blades effectively minimize feathering along the edges of the plywood and provide a much smoother finish to the cut surface.

Can I cut wood with nails?

When cutting through wood that contains nails, it is crucial to check if the saw blade has an anti-kickback feature.

This safety feature can be observed at the back of each tooth on the blade, where a small bump protrudes outward. Its purpose is to prevent the material being cut from suddenly propelling backward towards the machine or the operator.

This safety feature can be observed at the back of each tooth on the blade, where a small bump protrudes outward. Its purpose is to prevent the material being cut from suddenly propelling backward towards the machine or the operator.By reducing the aggressiveness of the blade, the anti-kickback feature helps to prevent the blade from getting stuck in the material. Having the anti-kickback feature significantly increases safety and prevents potential accidents or injuries.

At DART, all our TCT Circular Saw Blades with less than 40 teeth are equipped with anti-kickback, allowing you to safely cut through wood with nails.

Are circular saw blades and table saw blades the same?

Circular saw blades and table saw blades are generally interchangeable and compatible with various types of saws, including circular saws, table saws, miter saws, compound miter saws, plunge saws, and panel saws. These saw blades are designed to have a universal fit, allowing them to be used across different saw models.

However, it is important to ensure that the saw blade you choose is appropriate for your specific saw model. Checking the diameter, blade thickness and bore size of the blade is essential to ensure a proper fit and safe operation. Once you have confirmed the correct specifications, you can securely install the blade into your saw and proceed with cutting the desired material.

DART’s Circular Saw Blade Range.

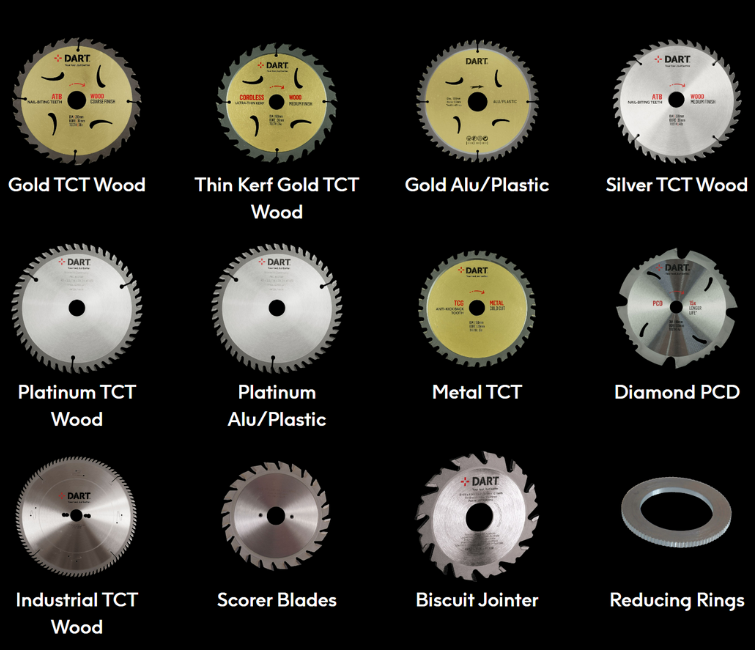

DART offers an extensive selection of circular saw blades designed to meet diverse needs in terms of sizes, tooth types, cut types, and material applications. Our high-performance saw blades are compatible with a wide range of circular saw machines. Whether you require wood, metal, aluminum, or plastic cutting capabilities, our comprehensive range has you covered.

To accommodate various cutting preferences, we offer blades with different tooth configurations. For swift cutting, blades with a lower tooth count are recommended, while for refined and precise finishes, blades with a higher tooth count are preferred. Regardless of the chosen tooth configuration, our circular saw blades consistently deliver exceptional cutting quality, prolonged service life, and unbeatable overall quality.

Gold TCT wood saw blades (thin kerf and standard) –

These professional TCT wood saw blades are designed for cutting through all types of wood, such as hardwood, softwood, MDF, hardboard, plywood and particleboard etc. The thin kerf option is for use in cordless machines to reduce power drain, and both blades feature a ATB Tooth configuration for the professional tradesmen. The unique gold coating creates a ultra low friction and wear resistance, with a reamed bore ensuring a precise fit on the spindle.

These professional TCT wood saw blades are designed for cutting through all types of wood, such as hardwood, softwood, MDF, hardboard, plywood and particleboard etc. The thin kerf option is for use in cordless machines to reduce power drain, and both blades feature a ATB Tooth configuration for the professional tradesmen. The unique gold coating creates a ultra low friction and wear resistance, with a reamed bore ensuring a precise fit on the spindle.The front bevel tooth form helps provide a superior quality cut, with anti-kickback for smooth action and safety during the cut. The body is hardened and tempered to maintain trueness. Reducing rings are also available for use on both types of blades, which allow you to

fit the blade on a machine safely when the bore size is different.

fit the blade on a machine safely when the bore size is different.The main difference between the thin kerf, and standard kerf blades is width of the blade. Kerf is the slit made by cutting with a saw, and this is measured by the width of the teeth.

Having a thin kerf blade will help to increase efficiency and runtime on cordless machines, it will remove less material and create a narrower slot. Whereas, the full kerf blade will help as it won’t waiver as much, compared to the thin kerf blade, and this would perform better when on a powerful corded saw, especially when you want a straight, accurate cut.

Gold TCT aluminum/plastic/laminate saw blades –

These professional TCT blades feature a triple chip ground (TCG) tooth configuration for a professional finish and long cutting life. Its unique gold coating creates ultra low friction and wear resistance.

These professional TCT blades feature a triple chip ground (TCG) tooth configuration for a professional finish and long cutting life. Its unique gold coating creates ultra low friction and wear resistance.They have a reamed bore to ensure a precise fit to the spindle, and the body of the blade is hardened and tempered to maintain trueness. These blades are suitable for cutting non-ferrous metals including aluminum, plastic and wood laminates.

Silver TCT wood saw blades –

These TCT blades feature an alternate top bevel (ATB) tooth configuration for universal wood cutting applications. Just like the gold TCT blades, these blades also have a reamed bore which helps ensure

a precise fit to the spindle. The body is also hardened and tempered to maintain trueness, and they are suitable for cutting soft and hardwoods, particle board, MDF, hardboard and plywood.

The difference between DART Gold TCT Saw Blades and DART Silver TCT Saw Blades, is the amount of tungsten carbide on the teeth. The gold saw blades feature a higher level to ensure longer product life, and an advanced cutting experience.

Reducing rings are available with this blade, and the DART range has sizes between 135mm to 305mm diameter, for coarse cutting through to fine cutting.

Platinum TCT saw blades –

These professional blades, manufactured in Germany to the highest specifications and include superior length of tungsten tip. Each tooth is diamond ground giving it longer durability, and the body of the blade is precise flattened for good cutting quality.

These professional blades, manufactured in Germany to the highest specifications and include superior length of tungsten tip. Each tooth is diamond ground giving it longer durability, and the body of the blade is precise flattened for good cutting quality.The ATB blades are suitable for clean cuts in softwood, hardwood and panel materials. Whereas, the TCG blades are suitable for aluminum, plastic and laminates.

These blades are available in standard and thin kerf options.

Metal TCT saw blades –

These blades feature a triple chip ground (TCG) tooth configuration for fast and clean cuts in various metal sections. This blade features an anti-kickback tooth for smooth action and increased safety during use. Its reamed bore ensures precise fit to spindle.

These blades feature a triple chip ground (TCG) tooth configuration for fast and clean cuts in various metal sections. This blade features an anti-kickback tooth for smooth action and increased safety during use. Its reamed bore ensures precise fit to spindle.It has a hardened steel body with lock embedded tungsten tip giving a spark free cut. This blade is suitable for cutting construction steel, aluminium, stainless steel, metal tube, U-steel, I-beam, and sheet metal cased aluminium panels.

PCD fibre cement saw blades –

DART’s quality polycrystalline diamond fibre cement blades come with a flat teeth configuration for use in specialist applications, providing durability and long life.

DART’s quality polycrystalline diamond fibre cement blades come with a flat teeth configuration for use in specialist applications, providing durability and long life.They feature a extra large gullet design which helps to minimise dust and improves the removal of material. The blade provides a smooth, clean and accurate cut, and lasts 15x longer compared to a standard TCT blade.

It is suitable for cutting aggregate decking, composite decking, compressed concrete, MDF, fibre cement and other ultra hard materials.

Industrial TCT wood saw blades –

These high quality TCT industrial wood-cutting saw blades manufactured to satisfy the demands of the professional. These are suitable for industrial applications and fixed bed machines with blades for ripping, cross-cutting and panel trimming, and come in diameters from 250mm to 500mm.

These high quality TCT industrial wood-cutting saw blades manufactured to satisfy the demands of the professional. These are suitable for industrial applications and fixed bed machines with blades for ripping, cross-cutting and panel trimming, and come in diameters from 250mm to 500mm.These also feature a reammed bore which ensures a precise fit to the spindle. The superior length of the tungsten tip gives maximum number of re-sharpenings. The body of the blade is laser cut from hardened steel, tempered and tensioned, complete with euro slots, providing you with a extremely strong, quality blade.

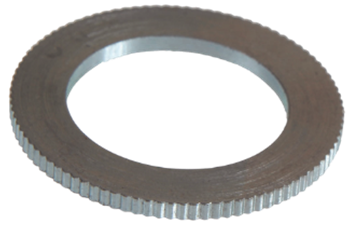

Reducing rings –

DART’s quality reducing rings help to ensure that blades fit safely to your machine when the bore size is different. They are accurately machined with reamed bores and splined outside edges give a precise fit.

DART’s quality reducing rings help to ensure that blades fit safely to your machine when the bore size is different. They are accurately machined with reamed bores and splined outside edges give a precise fit.Please note, the ring must be inserted correctly; pressed or glued into the body of the blade. Take extra care when mounting the saw blades onto a saw machine spindle when using the reducing rings, and do not use the reducing rings when the saw flange is not more than 5mm diameter bigger that the original saw blade bore size. These reducing rings are for use in DART saw blades only.

Saw Blade Compatibility

From thin kerf blades for cordless machines such as Dewalt Flexvolt Saws, to a platinum, German-manufactured TCT blade suitable for a Festool TS55C plunge saw, DART blades are manufactured to give you the better choice for your saw. DART blades are perfectly matched to your machine.

Interest in purchasing a DART circular saw blade, click here to find your nearest DART stockist.

We love to see our DART products in action! Be sure to tag DART Tool Group on Facebook, Instagram and LinkedIn to share how a DART circular saw blade made your life easier!

Kester Paterson | DART Tool Group